Simple products

On this page, you will find a variety of different products that I made using a variety of machinery such as the Millex CNC. These simple little projects helped me learn essential manufacturing skills, such as clamping techniques, feeds & speeds, depth of cut, etc.

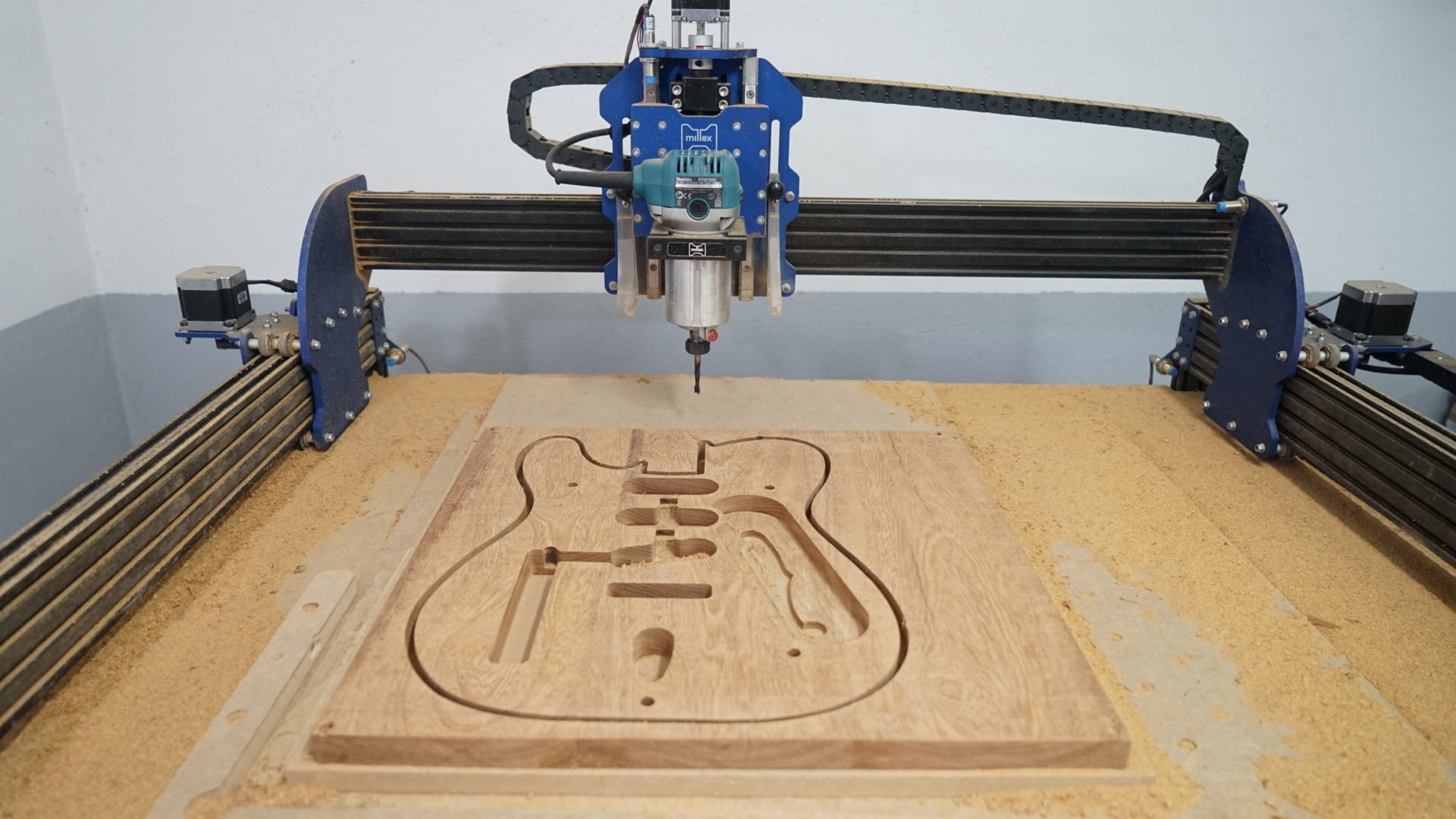

Electric guitar

What did I learn?

With this project, I learned how to program the CNC to mill a single part on two different sides.

The process:

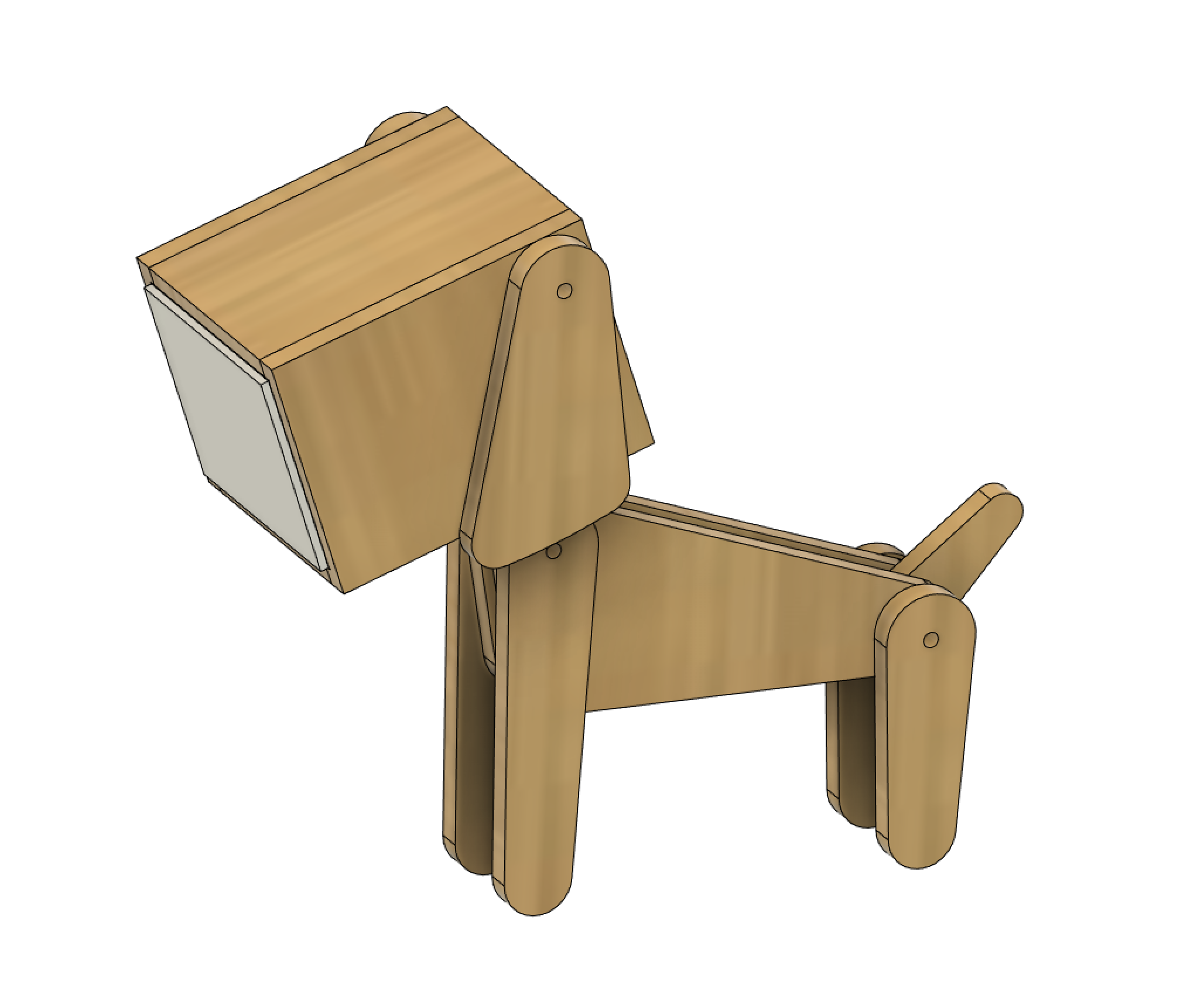

Dog shape lamp

What did I learn?

I learned how to modify the milling parameters and set up the CNC to machine polymers such as acrylic.

The process:

Executive Desk Name Plates

What did I learn?

I learned how to engrave on aluminum using a 30º milling bit as well as how to polish and give different types of finishes to aluminum.

The process:

Slingshot

What did I learn?

First, I learned the optimal settings for milling aluminum. And secondly, I continued to learn how to set up the code to mill the slingshot on both sides, doing operations such as pocketing or chamfering.

The process:

Vitruvian Man

What did I learn?

With this project, I learned how to vectorize an image to later import it into the CAD software.

The process:

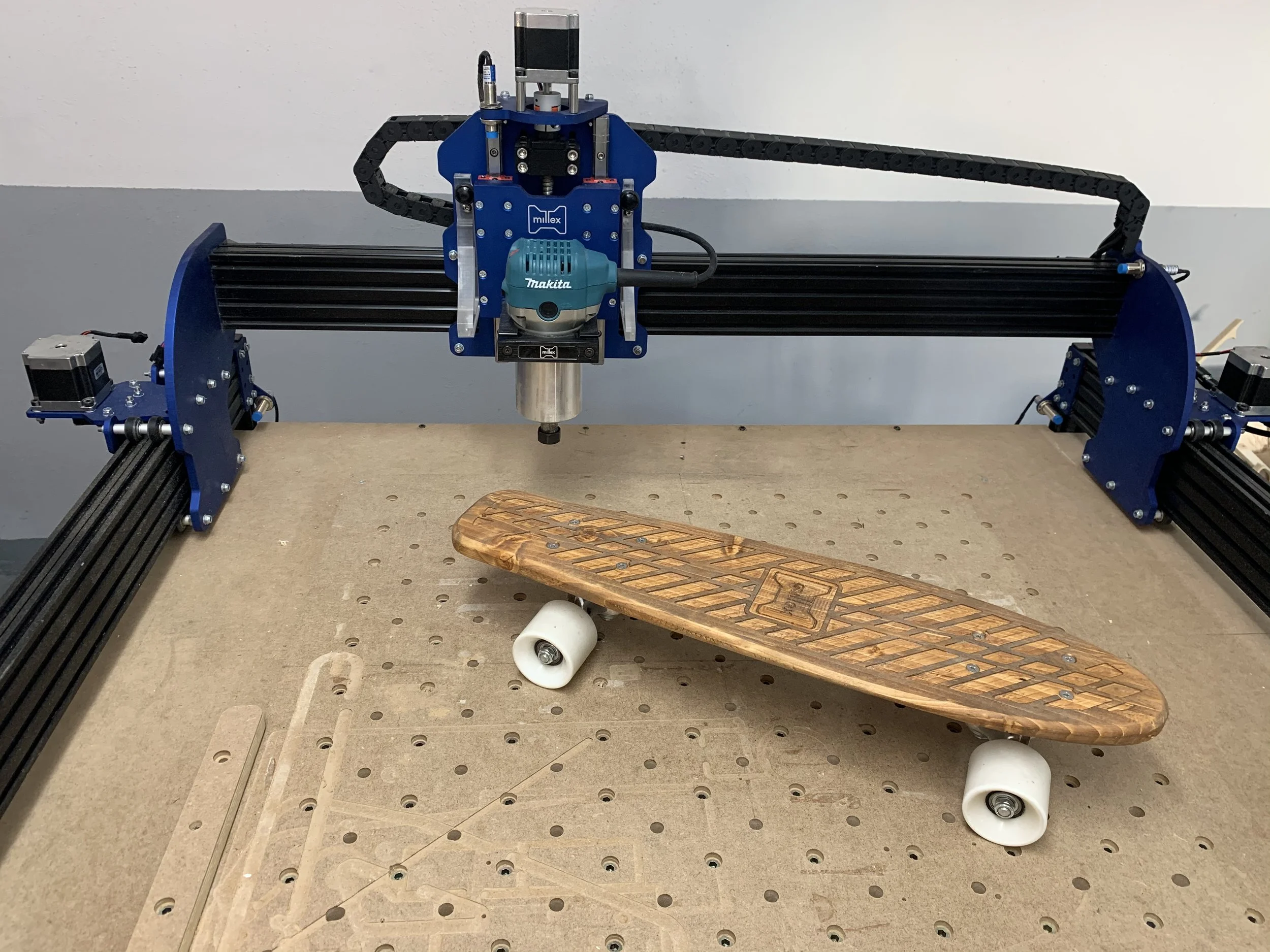

Mini longboard

What did I learn?

With this project, I learned how to design and mill organic shapes, as well as how to program the CNC to mill a single part on two different sides.

The process:

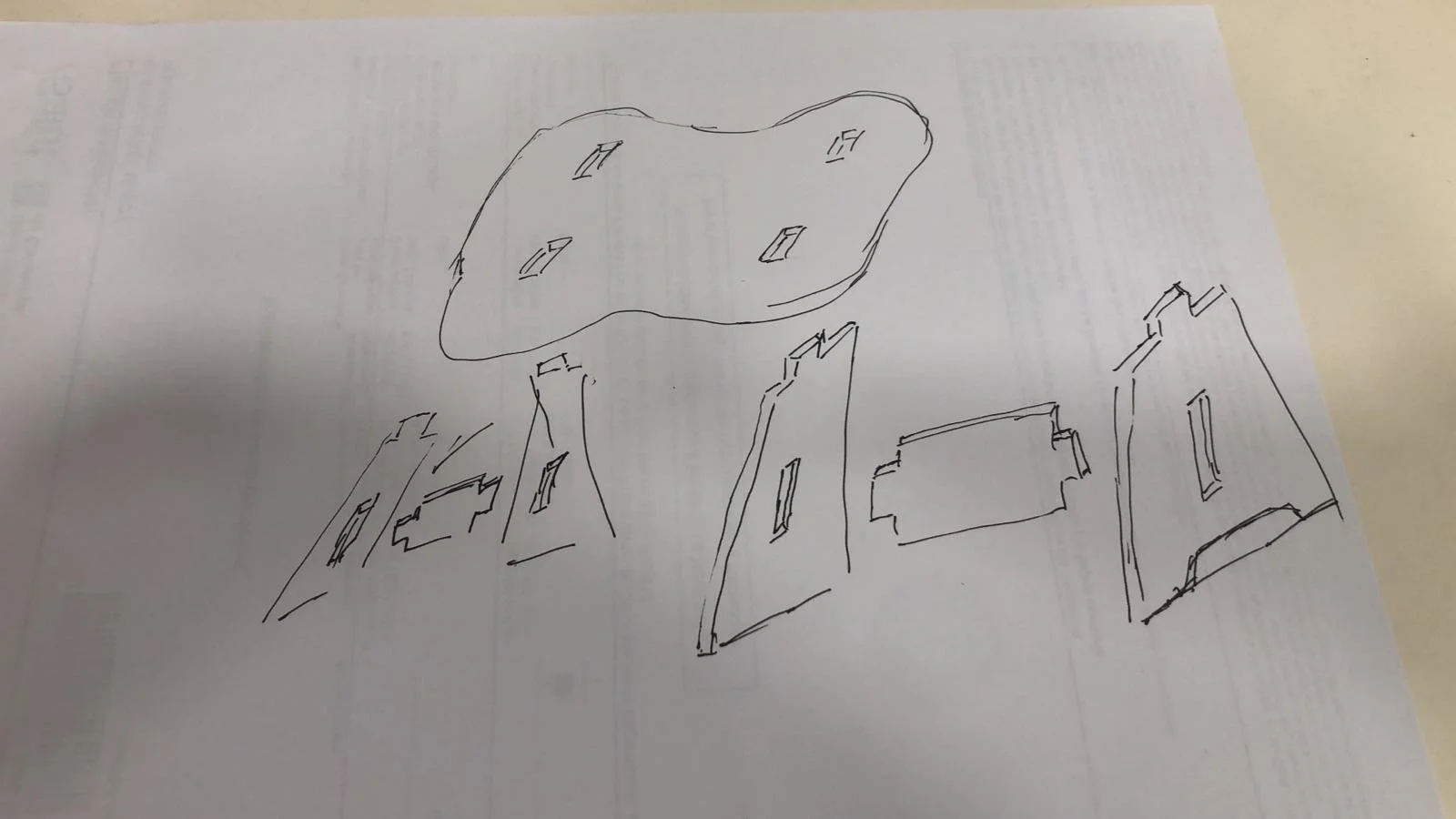

Stool

What did I learn?

With this project, I learned how to design joints with the necessary tolerances to press all the pieces together without using any glue, screws, or nails.

The process:

Valentine's Day Box

What did I learn?

With this project, I learned how to prepare the CNC to evacuate all the chips when milling a very deep part. I realized how important it is, and the risks that can come with not paying enough attention to this.

The process:

Birdhouse

What did I learn?

How by playing with post-processing techniques you can obtain different fascinating textures and results.